QR Codes will soon be appearing everywhere on clothing labels in the coming months and years. What are they for? Can we trust this information? Consumers’ demands for transparency are prompting players to provide more information about the manufacturing of their products. This becomes a strategic issue for brands, provided they have something to say.

The rules related to consumer information are going to change. Soon, the upcoming Environmental Display directive will apply to clothing just as it does to appliances, to inform customers about the product’s footprint. A grade or letter will soon appear with the goal of providing relevant information about the product’s environmental footprint.

Sommaire

Is grading a garment enough?

Probably not. If this grade reflects the reality of the product’s manufacturing, it will be useful in helping customers make their choice. However, it will not answer the specific questions posed by customers in stores about the made in and made how:

- Where was the garment made (not just the assembly but the entire supply chain)?

- Under what social conditions?

- What is the carbon footprint?

- What is the level of pollution generated?

And in the case where the grade does not reflect the real environmental impact of the product, this obviously poses the problem of potentially misleading the consumer and penalizing or favoring a company. Because the textile industry is very fragmented, often opaque. Most brands have little knowledge of their production chain. Under these conditions, how can we have reliable and secure data to define a grade?

At each manufacturing stage, from the cotton field or polyester factory to the store, there are 3 possible scenarios:

- The most committed players who have a very advanced and rigorous approach to reducing impact

- Players who are engaging in a process of improvement (recently) and want to do it as well as possible

- Cheaters and those who do not care about preserving the environment or the social conditions of their employees

The purpose of environmental labeling is to value the first and help the second accelerate for the protection of the earth.

Traceability: a strategic shift for brands

Now, many brands are taking up the issue of traceability for several reasons:

- It becomes essential to know and control one’s supply chain from end to end to engage in a serious CSR approach and achieve sometimes loudly announced goals

- Potential threats to social and environmental aspects that weigh on a brand’s reputation can affect the value of companies

- Customers and distributors are increasingly demanding on these criteria, and they expect proof. Mere declarations are no longer enough. Brands must demonstrate their commitment or risk being disqualified.

Labels used in textile industry, including QR codes and RFID tags attached to fabrics, serve as physical carriers of traceability data, providing verifiable information for both manufacturers and consumers. By implementing these physical traceability tools, brands ensure visibility at every stage of the process, supporting downstream and upstream tracing.

Calculate the eco-score of your clothing

Master the environmental impacts of your designs with our dedicated platform.

Schedule a demoScanning a QR code on a label to say what?

Today, the legal information on a garment’s label is quite limited since it stops at the material composition. The country of the last manufacturing step is not even mandatory.

Today, the legal information on a garment’s label is quite limited since it stops at the material composition. The country of the last manufacturing step is not even mandatory.

Technology now allows for a lot of information to be provided through a mobile app or software. But this information must be useful and reliable.

Several applications exist. Some position themselves as defenders of the consumer by grading brands based on algorithms defined according to their own perception of what is right or wrong in our industry. Others provide a solution for brands to inform their customers about how products are made. But what value to give to data communicated through the printing of a QR code on a label if it is not verifiable and secure? This is the whole difficulty of the exercise and the potential danger of discrediting an entire profession.

It is not reasonable to judge a product or articles based on mere declarations. Similarly, the best technological solution will not completely avoid fraud and the transmission of erroneous data. However, actors who communicate must take their responsibilities and all precautions to provide objective and sincere information.

But what value can be given to data communicated through a QR code printed on hang tags or barcode labels if it is not verifiable and secured? This is the whole difficulty of the exercise and the potential danger of discrediting an entire profession.

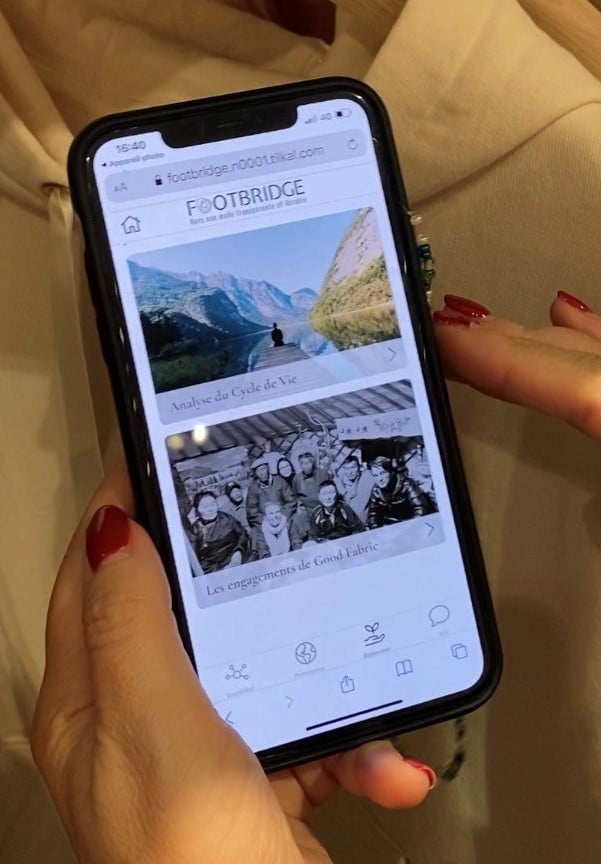

Having precise information on the places and conditions of manufacturing from end to end associated with information on the life cycle analysis is what FOOTBRIDGE offers through its mobile app thanks to data collected by all the actors in the supply chain, auditable and secured by blockchain.

Tracing throughout the life cycle

Another interest in marking a garment with a QR code or RFID chip is to be able to follow it throughout its use, its possible resale, and its recycling. This implies not sticking the QR code on a label or hang tag but integrating it into a woven label sewn into the fibers, inside the garment. Moreover, this type of labeling will allow for labels integrated into the fabric, always readable after washing the product and robust. It is then possible to know the manufacturing conditions at the time of second-hand purchase and facilitate its recycling through a circular chain thanks to precise information on the fabric and components, which facilitates the identification of the garment.

Once again, traceability is a long-term but essential work to engage in a structured CSR strategy and communicate serious information to its customers. But, without a doubt, it is an effective means to strengthen the trust of its customers. Providing transparency is a strong lever of attractiveness. The day after tomorrow, this transparency will become the norm, and actors who have not taken the step risk being disqualified.

Moreover, a mobile application of this type is a formidable tool for information and communication to tell the true story of the product in addition to the Environmental Display note, a positive point for the fashion and textile sector.

The perfect world does not exist. But we can approach it step by step. It remains to accelerate the pace ????

FOOTBRIDGE is a traceability and impact analysis platform dedicated to the textile sector developed in partnership byGOOD FABRIC, a pioneer of sustainable fashion, and TILKAL, an expert in traceability and blockchain technology.

8 key questions from the article

- What is the importance of geographical traceability for a textile product?

Geographical traceability is essential for a textile product because it ensures increased transparency about the origin and manufacturing conditions. This not only helps combat controversial practices like forced labor but also gives consumers a better understanding of the environmental and social impact of their purchase.

Traceability systems use physical carriers like traceability tags and RFID chips to convey specific information throughout the supply chain, from manufacturer to store. Modern technologies like QR codes printed on clothing labels or barcodes for textiles further enhance label security and carry traceability data in a way that prevents falsification.

By scanning a QR code on a clothing tag with a dedicated mobile app, consumers can now access details about traceable garments, from their origin to their environmental footprint, supporting a fashion industry more focused on traceability.

- How does environmental labeling on textile labels influence consumer choice?

The most rigorous textile certificationsplay a crucial role in raising consumer awareness about the impacts of their purchases. Since January 1, 2023, the anti-waste law for a circular economy reinforces the importance of sustainable textiles labeling. Apparel distributors and manufacturers must meet the requirements of environmental transparency, ensuring compliance with stricter standards.

By including traceability QR codes or other physical identification carriers on products, manufacturers can communicate reliable data about traceable textiles and their lifecycle through dedicated applications that read and interpret this data.

- What role does the France Terre Textile label play in the textile industry?

The France Terre Textile label guarantees that the majority of a textile product’s manufacturing process, including spinning, weaving, and finishing, takes place in France.

This label, aligned with the principles of textile traceability, emphasizes quality, local origin, and environmental responsibility. It represents manufacturers’ commitment to offering greater transparency and promoting ethical production practices.

- What are the challenges of implementing the traceability label in the textile industry?

The main challenges related to implementing the traceability label in the textile industry include the complexity of international supply chains and the need for advanced technologies to ensure precise traceability.

Moreover, standardizing the information displayed on labels and raising consumer awareness about the importance of traceability remain significant challenges. The adoption of the AGEC law has encouraged manufacturers to adopt more transparent practices, but much remains to be done to achieve complete and effective traceability.

- How do technological innovations, such as QR codes, improve the traceability of textile products?

Technological innovations like QR codes and smart tags are crucial in improving the traceability of textile products.

By scanning a QR code on a garment’s label, consumers can instantly access detailed information about the product’s origin, manufacturing stages, and environmental impact.

These technologies offer increased transparency and facilitate the tracking of products’ life cycles, contributing to a more responsible and sustainable textile sector.

- What is the relationship between the duty of vigilance law and the textile traceability label?

The duty of vigilance law, adopted in 2017, requires large companies to identify and prevent human rights and environmental risks across their supply chain. This law complements traceability labels by holding manufacturers accountable for traceability data and ethical practices.

By ensuring product traceability and highlighting the batch of products involved in manufacturing, this law strengthens fabric traceability and promotes ethical transparency. The implementation of traceability systems with physical identifiers like traceability tags enables brands to authenticate and track products while ensuring compliance with industry standards.

- How does the traceability label contribute to a more ethical and sustainable fashion?

The traceability label contributes to a more ethical and sustainable fashion by providing key information about the provenance, manufacturing methods, and environmental impact of textile products.

By highlighting these aspects, it encourages consumers to choose brands that adhere to sustainable and ethical practices, such as those using ecological materials, respecting workers’ rights, and minimizing their carbon footprint.

- What is the impact of the traceability label on combating waste in the textile industry?

The traceability label, often enhanced with QR codes or traceability stickers as physical data carriers, plays a key role in fighting waste in the textile industry. It allows consumers to make better choices by providing information on product quality, batch numbers, and environmental impact through digital platforms that read these physical carriers.

By encouraging the purchase of durable, high-quality items, labels used in the textile industry support the circular economy and reduce waste. For manufacturers, barcode labels for textiles and qr code traceability enable precise tracking of products throughout the supply chain, facilitating recall processes when necessary and pinpointing affected products.

In this way, traceability labels and tags not only reduce excessive consumption but also ensure resources are managed efficiently to promote sustainability.