When it comes to tackling the environmental impact of a garment, it’s essential to understand not only the major environmental issues in the textile industry, but also the reality on the ground at each stage of manufacture, use, and end-of-life. The textile industry, in particular, is one of the most polluting industries in the world, and to understand why, it’s essential to analyze each phase of its life cycle.

It’s a complex issue because calculating a Life Cycle Assessment (LCA) is one thing (not so simple – we will come back to that). But just staying behind an Excel spreadsheet will never solve any problems. Doing better involves being on the ground, in contact with those who are skilled, and thinking together about how to improve the environmental footprint of the textile sector.

Currently, many believe that to be ‘green,’ one should use recycled materials… Of course, this is a promising avenue, but it’s only one of the solutions to the pollution from the textile industry, for several reasons:

- It is indeed a major challenge of our decade. But as of now, there are no operational circular industries in Europe capable of handling large volumes in an optimized way to be economically viable and provide a good quality level. Numerous initiatives are underway, be it in mechanical recycling or clean chemical recycling, but we still need to be patient.

- Recycling potentially toxic materials makes no sense unless we can address the problem during the recycling process, noting that this process must, of course, be clean.

- Plastic bottle factories have been set up in China to reuse these new bottles and make recycled polyester yarn! So, when choosing a recycled material, it’s essential to trace the supply chain and identify the processes used.

- Today, over 95% of the textile products sold are made with ‘virgin’ materials. So, if we truly want to tackle the problem, we must FIRST deal with the impact of raw materials.

- In any case, the need for virgin raw materials will remain huge, even if circular industries develop.

Sommaire

What is the textile industry? What pollution does it cause?

The textile industry is a major polluter, producing harmful emissions that damage the environment and human health. This water-intensive industry requires a considerable amount of resources (especially during the early stages of production, when cotton is grown), and also produces large quantities of solid waste, particularly textiles that are not biodegradable. What’s more, dyeing and finishing a garment account for around 36% of chemical discharges into the environment.

As a result, the textile industry is the third-largest polluting industry globally, following agriculture and transportation, because each garment produced releases nearly 100 chemical substances during its life cycle.

The textile manufacturing process utilizes artificial elements, energy, and tons of liters of water, all contributing to pollution in the textile industry. One of the chemicals used in the manufacturing process is titanium dioxide (TiO2), an inorganic compound used as a white pigment or catalyst. TiO2 is known to cause acid rain when it reacts with water and air.

Finally, the life cycle of a textile involves numerous stages that lead to water pollution from textile industry and air pollution, further exacerbating the environmental pollution.

It all starts with natural and synthetic fibers that are grown, harvested, and transformed into yarn. The spinning process requires a lot of energy as it uses a significant amount of electricity or even gasoline to operate the machines that spin the fibers. The dyeing process, on the other hand, uses many artificial substances and a lot of water, and sometimes this water is not adequately treated before being discharged into nearby rivers or wells!

How do we measure textile pollution? What does LCA mean?

According to the definition by ADEME, Life Cycle Assessment (LCA) involves cataloging and quantifying the physical flows of materials and energy throughout a product’s life cycle, encompassing all related human activities. This method has been standardized through ISO standards 14040 and 14044 (from the European Union).

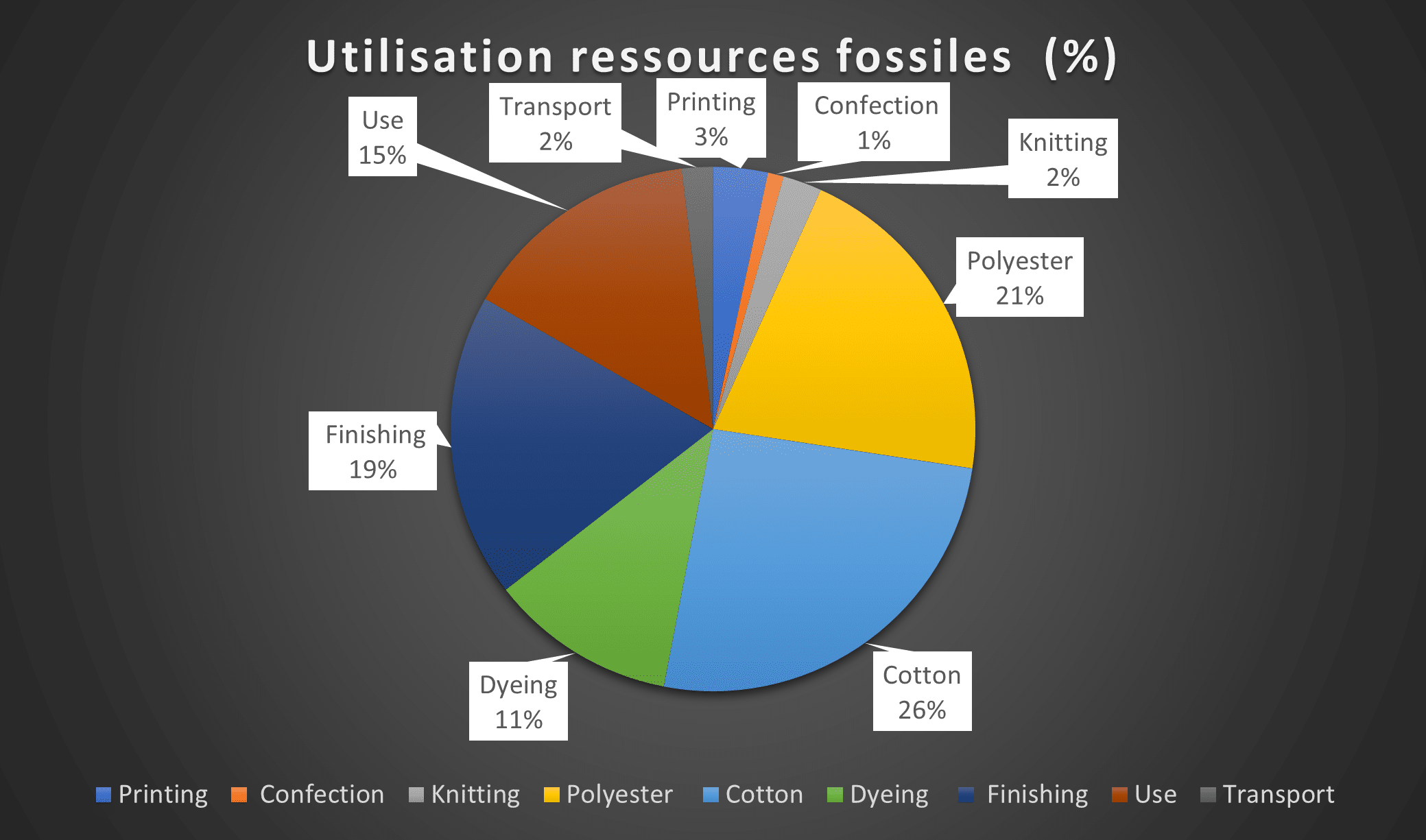

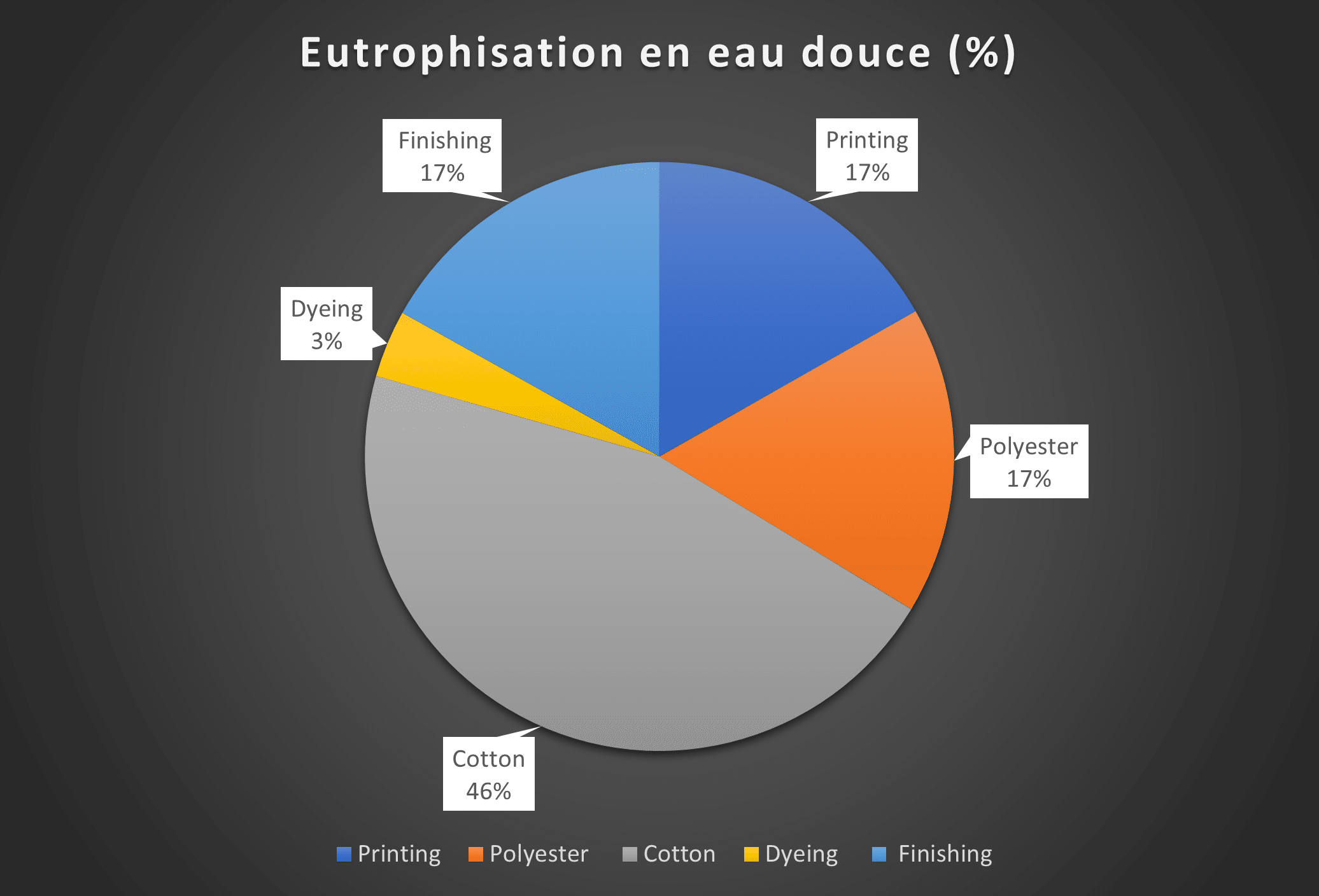

Therefore, it should allow for the measurement of the environmental footprint at all stages of the product’s life, focusing on different impact indicators, especially the three main ones:

- Climate change

- Eutrophication of freshwater

- Use of fossil resources

credit : Footbridge

Life Cycle Analysis (LCA) thus allows for identifying at which stage of the chain a product is most polluting, based on the materials used, its production methods and locations, as well as the number of washes it undergoes after purchase or how its end-of-life is managed.

LCA adheres to a standardized protocol that enables the comparison of one product’s results with another’s (and from one brand to another). Therefore, all parties communicating about a Life Cycle Analysis are supposed to use a similar protocol to ensure the accuracy of the information provided to consumers.

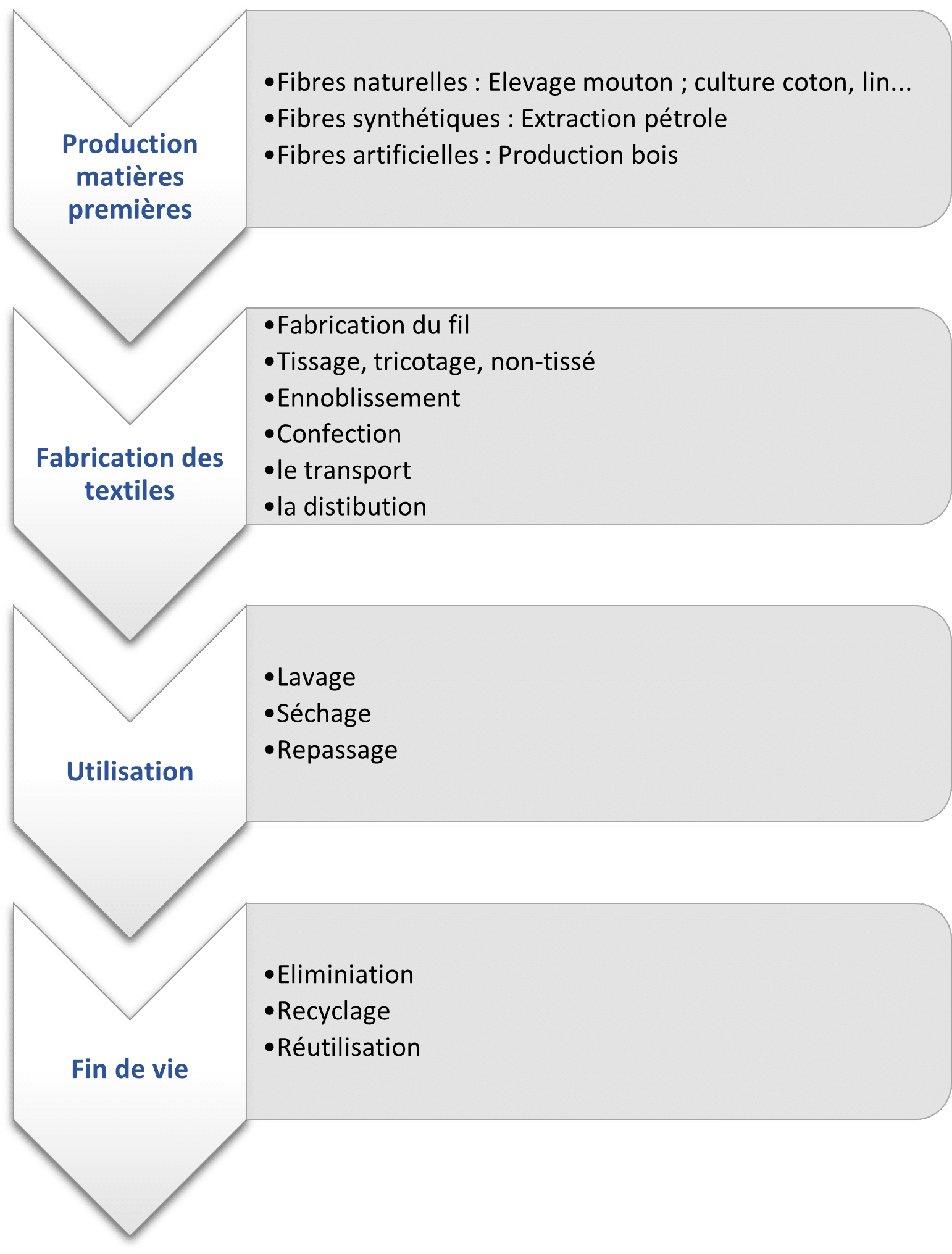

The scope described below outlines the stages considered during the study.

Credit : Footbridge

Example of an LCA (Life Cycle Assessment) calculation for a sleepsack worn and washed 30 times (functional unit).

credit : Footbridge

Credit : Footbridge

Credit : Footbridge

The three impact factors are measured across the entire product lifecycle, from design to end-of-life, including distribution and usage.

FOOTBRIDGE also allows for the measurement of these three factors, comparing them with a similar control product (the Life Cycle Assessment (LCA) of the control product is calculated based on a global production average reference).

Powered by Footbridge

Beyond the standard, it’s crucial that the Life Cycle Assessment (LCA) can provide an accurate depiction of a product’s repercussions. This requires reliance on reliable and precise data which is not always available.

For instance, consider a conventional cotton T-shirt (cultivated using the most polluting method in the world) and the same T-shirt made of organic cotton certified by GOTS and FLOCERT from start to finish. The environmental impact of textile industry and the environmental and social impacts of these two products are diametrically opposed.

In this case, the LCA – and therefore the calculation process – must be able to precisely demonstrate the difference between these two products. Otherwise, the consequences could be disastrous for the sustainable development of our textile and apparel industry.

Every year, the world consumes 130 billion garments.

This excessive consumption of fashion and clothing production has led to an even greater pollution from the textile industry. The demand for fast, cheap fashion continues to fuel the rise of fast fashion, leading to increased textile waste and contributing to global water pollution and air pollution in textile industry. It’s not just about production, textile and clothing purchases are skyrocketing, and with them, the impact on environment.

The primary factors contributing to this impact include:

- The use of synthetic materials such as acrylic, nylon, and polyester, which are produced from fossil fuels, is one of the leading causes of pollution from the textile industry.

- The consumption of water in the manufacturing process, especially in regions where water is scarce, adds to water pollution from textile industry.

- The discharge of toxic chemical elements into the air and water, including carcinogens and endocrine disruptors.

- The disposal of clothing waste, which often ends up in landfills or is incinerated, releasing harmful pollutants into the air.

Textile companies are beginning to take steps to lessen their environmental footprint, but there is still a long road ahead. We must demand more sustainable practices from the fashion industry and make choices that minimize our own environmental impact.

Eco-design must rely on multiple factors. Life Cycle Assessment (LCA) helps us understand the stakes for each type of product, but it’s not the only tool and, in any case, it’s just one step in the eco-design process.

As mentioned in a previous article – L’éco-conception : possibilité ou nécessité ? -, eco-design is primarily common sense. It’s also about gaining expertise by asking the right questions and thoroughly investigating the issues. It demands a high level of scrutiny to find answers to all questions and a lot of energy to change that don’t align with sustainable production.

The good news is that today everything is much simpler as everyone is getting involved. The momentum is massive and forces all stakeholders to reevaluate their practices.

The fashion industry is rapidly evolving. While it took a long time to start, there’s now a massive momentum to rethink the business model of the textile sector. This momentum is encouraging all players, from textile companies to consumers, to assess their practices and make changes that lead to more sustainable fashion and reduced pollution from the textile industry.

In some cases and for certain products, the different production stages are not the only ones involved. The consumer plays a key role in the pollution in fashion industry, especially in the use phase. When consumers wash, dry, and dispose of their clothing, they contribute to water pollution and textile waste. Purchasing low-quality, disposable garments from fast fashion brands that quickly end up in landfills is a consumer decision that has direct repercussions on our environment each year.

Calculate the eco-score of your clothing

Master the environmental impacts of your designs with our dedicated platform.

Schedule a demoWe are all affected by textile pollution.

Brands and manufacturers can therefore work together to reduce their impact on the environment. If all stakeholders in the chain commit to rethinking their model and making the right choices, our industry can become virtuous by drastically reducing its global carbon emissions.

The equivalent of a dumpster of clothing is thrown away every second around the world.

The movement is underway. It took a long time to start, but it has finally begun and is quickly gaining momentum. At GOOD FABRIC, we see intentions being declared and progress being made every day.

No verified Life Cycle Assessment without end-to-end traceability

However, to truly measure the environmental cost of a garment, it’s not sufficient to merely rely on default values from databases without considering what’s actually happening, for instance, at a spinner or at the dyer who did the printing.

Because between two dye houses in the same country, the 1st using electricity from a coal-fired power plant and discharging its toxic waters into the stream behind the factory, and the 2nd with photovoltaic panels installed on the factory roof, certified GOTS, and perfectly treating its waters, the difference is clearly night and day!

Yet, if we only refer to default values from databases without caring about what’s actually happening in the factories, it’s impossible to perform an accurate and relevant calculation of this impact. For that, it’s essential to know all the players in the supply chain… and choose them wisely.

That’s the whole challenge of the task, as there’s often a chasm between theory and real life. And this can lead to misleading information being provided to consumers.

Environmental Labeling, Life Cycle Assessment (LCA): What’s the Difference?

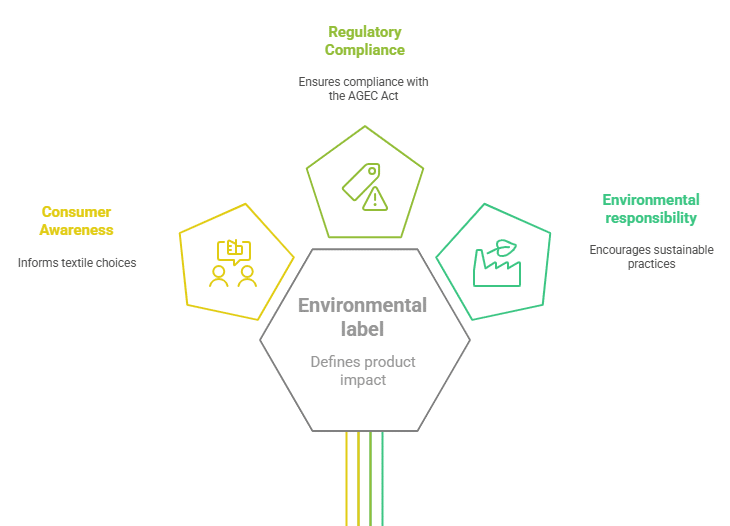

Everyone talks about environmental labeling, but no one really knows what it is! That’s understandable since this regulation, linked to the AGEC law and applicable to all textile products, is not yet defined. It aims to assign a grade (or rather a letter A, B, C, D, or E) based on the product’s environmental impact, similar to how nutritional competence is indicated on food products.

Beyond the question of which criteria will be used to define what makes a garment “eco-responsible” or not, the topic is very sensitive. Simplifying a complex issue to the extreme can lead to unintended consequences, sometimes opposite to the initial goal.

LCA and environmental labeling are related concepts, but they should not be confused. They use the same method and calculation process. LCA measures the various impacts of a product from the cotton field to the end of its life cycle, while environmental labeling provides the consumer with a grade based on how the product’s impact compares to the average impact of similar products.

Life Cycle Assessment is therefore useful in the eco-design of a product, that is, for the teams that create and develop it.

Being able to communicate the true story of your product, explaining where and under what conditions it was made from start to finish, is the only condition that truly allows for control over product communication and brings transparency to the consumer.

Brands that achieve this goal will be the next leaders in their market.

credit photo : Christophe Simon/AFP

In the meantime, it is necessary to move forward with this demanding approach because it is the only viable path for brands that truly want to commit and avoid greenwashing. It is a long-term profession that involves proceeding step by step, initially focusing on the main sectors.

Implementing real traceability by holding each link in the chain accountable for the data they provide and by monitoring it ensures that we no longer rely on mere grand statements without truly knowing.

Claims must be verified. Where did the material come from, and under what conditions was it produced?

Can we ignore the social impact of the textile industry?

Is it possible to care about the environment without caring about people? Obviously not (at least from our point of view)! So why won’t the Agec law on environmental labeling take into account the working conditions in the production chain, given the environmental issues in textile industry are intertwined with these concerns?

Some will tell us that we can’t do everything. You have to pick your battles, but almost everyone agrees that you have to ensure good social conditions in the production of your collections. This is all the more critical given that a brand’s reputational risk lies first and foremost in its respect for workers. The various humanitarian scandals our industry has experienced and the risk of boycotts, particularly by new generations, mean that principals must face up to their responsibilities.

As we see, textile industry pollution is not just about pollution from textile industry but also about social impact.

That’s why it’s essential to know your suppliers, and not just the manufacturers. Here, too, the subject is particularly complex, since guaranteeing good working conditions is self-evident, but the conditions associated with this profession do not have the same meaning in France, Portugal or Bangladesh. Ensuring application of the rules of labor law defined by the ILO is a minimum requirement.

A brand’s responsibility extends not just to row 1, but to the entire chain.

- How safely are chemicals handled in dyeing plants?

- How is water treated to avoid poisoning neighboring villages?

These are just a few examples of how a social audit of a garment factory (by a local auditor) is not enough to guarantee good working conditions.

On the other hand, when you raise the question of animal welfare to a nomadic herder in Mongolia, he simply doesn’t understand the issue. His animals are part of his family. For him, it’s unthinkable to treat his goats badly. They are a condition of his family’s survival in a very hostile environment, particularly in winter.

Obviously, the issue of animal mistreatment is one that needs to be tackled across the globe. But it cannot be considered a generalized problem. By the same token, there are many fine factories in every country that give priority to the quality of life of their workers. Conversely, there are bad examples in France too.

In short, when you want to reduce the environmental footprint of a garment and you detail all its polluting factors, you can end up with a headache. The first thing to do is to focus on the fundamentals, so as to make the most of your progress:

- Make a quality product that will last a long time

- Use responsible, certified and traced materials

- Guarantee product non-toxicity and worker safety

- Drastically reduce greenhouse gases and pollutants in the air and water.

For brands with a large number of suppliers, it is essential to use tools that allow them to structure and effectively manage the eco-design of their collections, alongside in-depth knowledge of their supply chains.

Sources

https://www.goodfabric.fr/laffichage-environnemental-pour-le-textile-est-ce-une-si-bonne-idee

6 key questions from the article

- Why is the textile industry such a major polluter in terms of water, chemicals, and textile waste?

The textile industry is one of the biggest environmental offenders due to its complex production cycle. Starting with raw material extraction, such as cotton farming, which consumes vast amounts of water, the industry continues with resource-intensive stages like spinning and dyeing. These processes release harmful chemicals into the environment and require large quantities of energy and water.

Additionally, the textile sector produces significant amounts of non-biodegradable waste. Dyeing alone contributes to approximately 36% of chemical discharge into water sources.

- What are the main pollutants from textile production that contribute to water pollution and emission of greenhouse gases?

Key pollutants in textile manufacturing include chemicals like titanium dioxide (TiO2), which, when mixed with water and air, contributes to acid rain. The dyeing process uses both artificial substances and large volumes of water, much of which is often inadequately treated before being discharged into rivers or groundwater.

These substances can significantly degrade ecosystems and water quality, while the textile production process also emits large amounts of greenhouse gases.

- How do we measure textile industry pollution and its environmental footprint through Life Cycle Assessment (LCA)?

Life Cycle Assessment (LCA) is a standardized method used to quantify and catalog the physical flows of materials and energy throughout a product’s life cycle, from production to disposal. This methodology, defined by ISO standards (14040 and 14044), allows for the measurement of environmental impacts across various stages.

Key indicators assessed in LCA include climate change, eutrophication of freshwater, and fossil resource depletion. By identifying the stages in the life cycle where pollution is most severe, LCA helps determine where improvements are needed in the textile sector.

- Why is Life Cycle Assessment (LCA) crucial for understanding the sustainability of textile production?

LCA is essential for understanding the environmental impact of textile products from their design phase to their end-of-life disposal. It helps identify which parts of the production process (e.g., raw material extraction, manufacturing, or disposal) are the most harmful.

By comparing the LCA results of different products, consumers and manufacturers can make informed choices about which products are more sustainable, like choosing organic cotton over conventional cotton, thus promoting sustainable fashion.

- How does fast fashion contribute to pollution and greenhouse gas emissions in the textile sector?

Fast fashion exacerbates the pollution problem by encouraging overproduction and mass consumption. Globally, 130 billion garments are consumed annually, which leads to huge volumes of waste and a significant environmental footprint.

This constant demand for cheap, quickly produced clothing results in high levels of greenhouse gas emissions, approximately 10% of global emissions come from the textile industry. The fast fashion industry is a significant contributor to textile waste and water pollution as well.

- Why are recycled materials only part of the solution to textile waste and pollution in the fashion industry?

Recycled materials are a step in the right direction but do not address all the issues. The main challenge is that Europe does not yet have operational circular industries capable of handling large-scale textile recycling in an economically viable and environmentally clean manner.

Moreover, the recycling process itself must be free of toxic substances, and even as recycling technologies improve, the demand for virgin materials remains high, making it impossible to rely solely on recycling to reduce the fashion industry’s environmental impact.