European regulations are making great strides towards making sustainable products the norm. With the ESPR (Ecodesign for Sustainable Products Regulation) and the Digital Product Passport (DPP), the European Union is imposing an unprecedented framework: defining, for almost all categories of goods, eco-design requirements (reparability, recyclability, robustness, resource efficiency) and digital transparency throughout the life cycle. For the fashion industry – clothing, textiles, footwear, leather goods – this means a structural transformation: an end to the destruction of unsold goods, the obligation to trace materials and processes, and the sharing of standardized information with customers, authorities and partners.

This article deciphers :

- ESPR and DPP operations,

- what the Commission is preparing specifically for textiles and footwear,

- deadlines and milestones to watch out for,

- the different impacts depending on company size and geographical location,

- the constraints… but above all the business opportunities that are opening up,

- a concrete action plan to help you adapt without losing competitiveness,

- and how Footbridge provides an operational response, ready for the DPP.

Sommaire

ESPR: a new single framework for ecodesign

ESPR (Ecodesign for Sustainable Products Regulation – EU regulation 2024/1781) replaces the 2009 Ecodesign Directive – limited to energy-related products – and extends the scope to virtually all physical goods placed on the EU market.

The aim is to extend the life of products, reduce their environmental footprint and promote circularity.

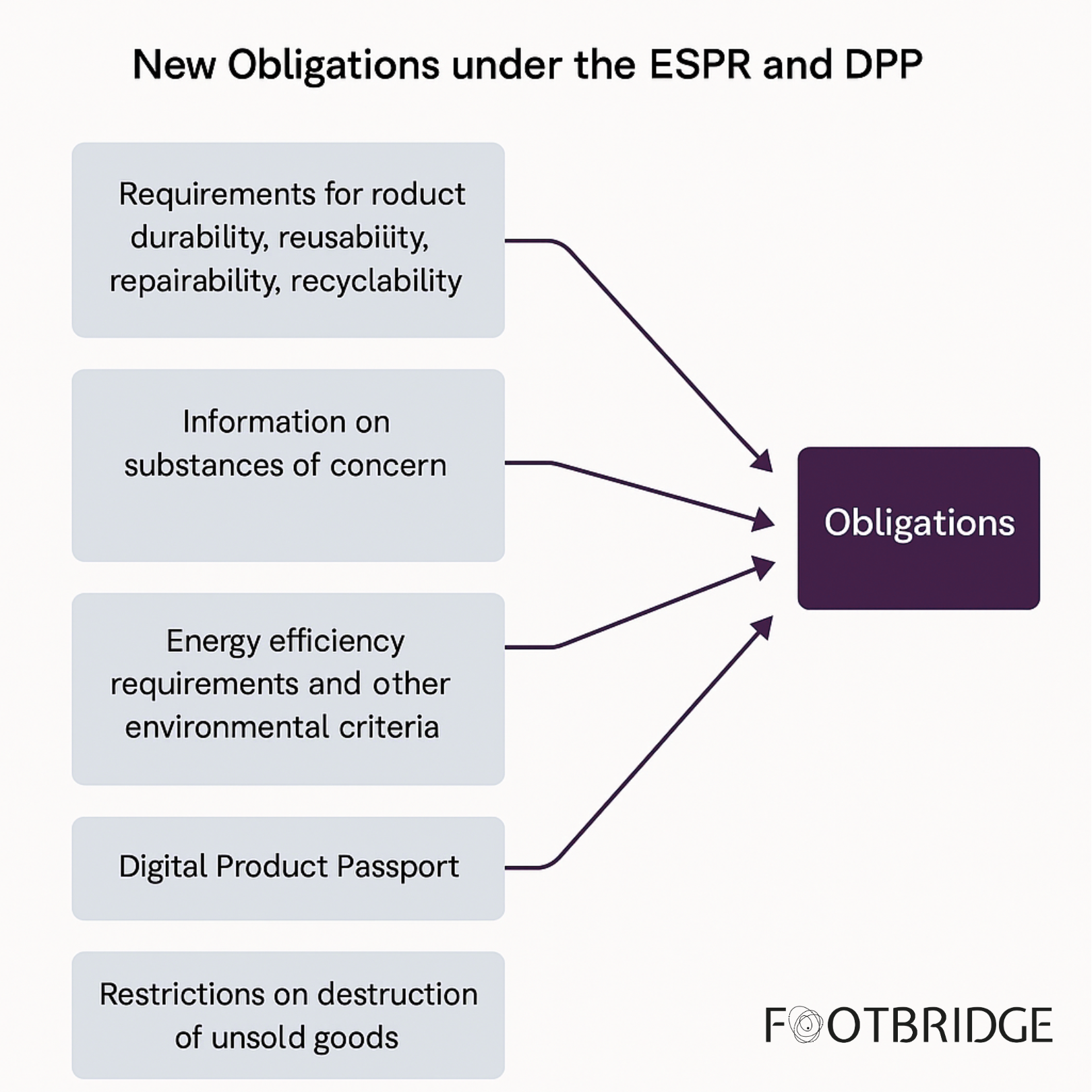

What ESPR changes in practice?

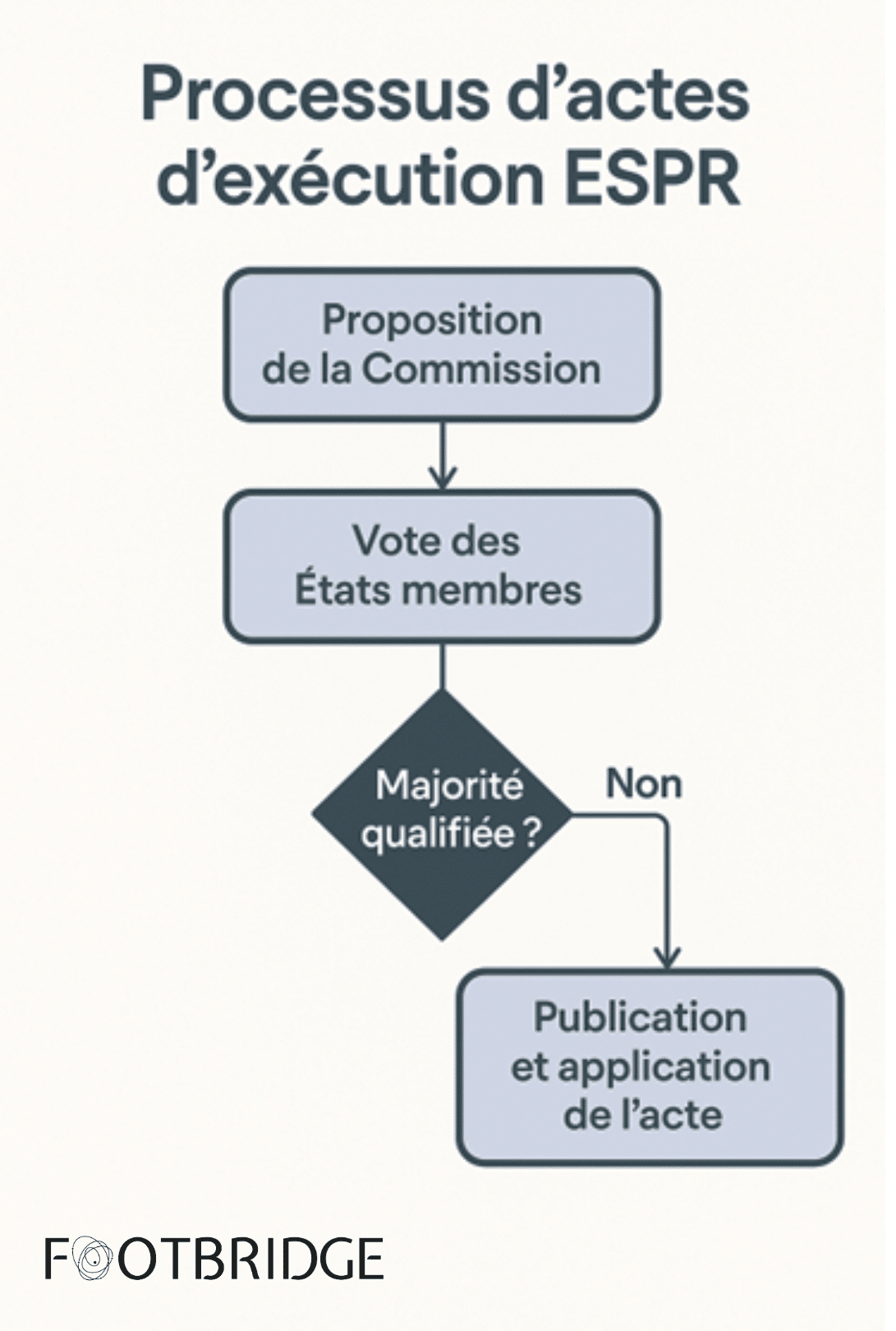

- A regulation, not a directive: it is directly applicable in all Member States, thus avoiding national divergences.

- Delegated acts by product family: the Commission does not publish a list of generic requirements. It adopts, after study and consultation (Ecodesign Forum, Member States, industry, NGOs), technical texts specifying :

- indicators and thresholds (durability, reparability, recycled content, etc.),

- information to be provided (repair manual, availability of spare parts, presence of substances of concern, etc.),

- formats and protocols for the digital product passport.

- Enhanced market surveillance and sanctions: in the event of non-compliance, national authorities can withdraw products, impose fines commensurate with the turnover and profits derived from the infringement, temporarily exclude companies from public procurement contracts, etc.

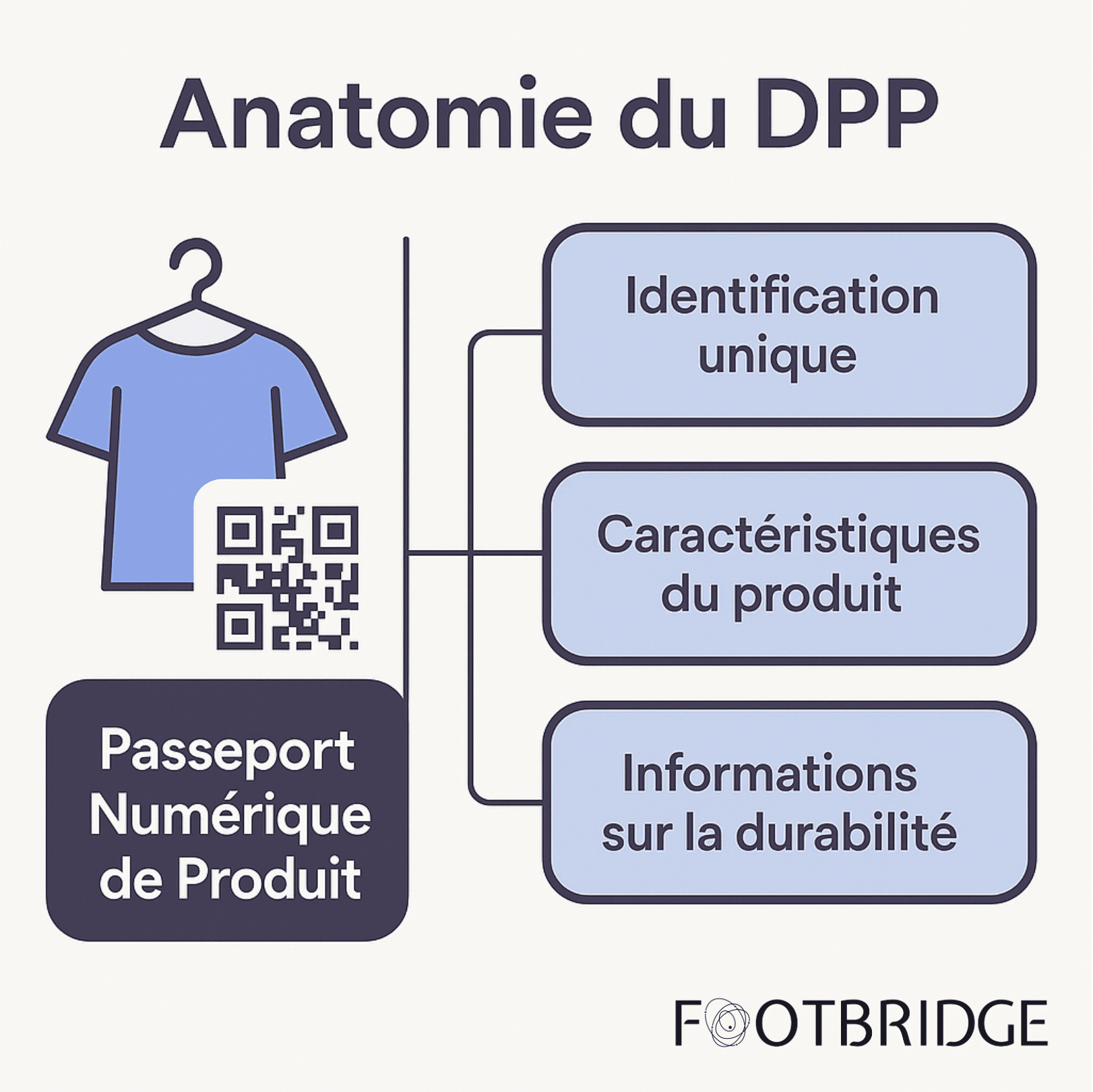

DPP: the digital product passport, the backbone of transparency

A central element introduced by ESPR is the Digital Product Passport (DPP). This is a kind of digital identity card that will follow each product throughout its value chain and life cycle.

The Digital Product Passport is the product’s digital twin. Accessible via a QR code, NFC chip or URL, it encapsulates standardized data on :

- product identity (unique ID, batch/series),

- composition (materials, percentages, substances of concern),

- its environmental performance (Lifecycle Analysis results, impact indicators),

- Repairability (instructions, spare parts, availability),

- end-of-life (recyclability, take-back channels),

- the players in the chain (locations and dates of the main processing stages),

- certificates and proof (labels, audits, quality controls).

The DPP has three aims:

- Inform and empower all players (consumer, distributor, repairer, recycler, authorities) to extend product life and improve circularity.

- Facilitate compliance: a harmonized format, connected to a European register, reduces the cost of proof and control.

- Create value: transparency, additional services (repair, second-hand), new business models.

Textiles, clothing, footwear and leather goods: the front line

The European Commission has prioritized the product families to be treated. Textiles and clothing are among the top priorities. Why is this?

- Significant environmental impact (water, energy, waste, microplastics, overproduction and unsold stock).

- Complex, globalized supply chains, requiring transparency.

- Rising consumption, rapid collection cycles.

Footwear and leather goods are included in the scope, but will be addressed via a specific study by the end of 2027 (different materials, specific processes). Dedicated requirements will soon follow.

Big news: ESPR bans the destruction of unsold consumer goods, starting with textiles and footwear:

- July 19, 2026: ban for large companies.

- July 19, 2030: same ban for medium-sized companies. Upstream, from 2025, large companies must report annually on the quantities destroyed, their weight and the reasons.

Calculate the eco-score of your clothing

Master the environmental impacts of your designs with our dedicated platform.

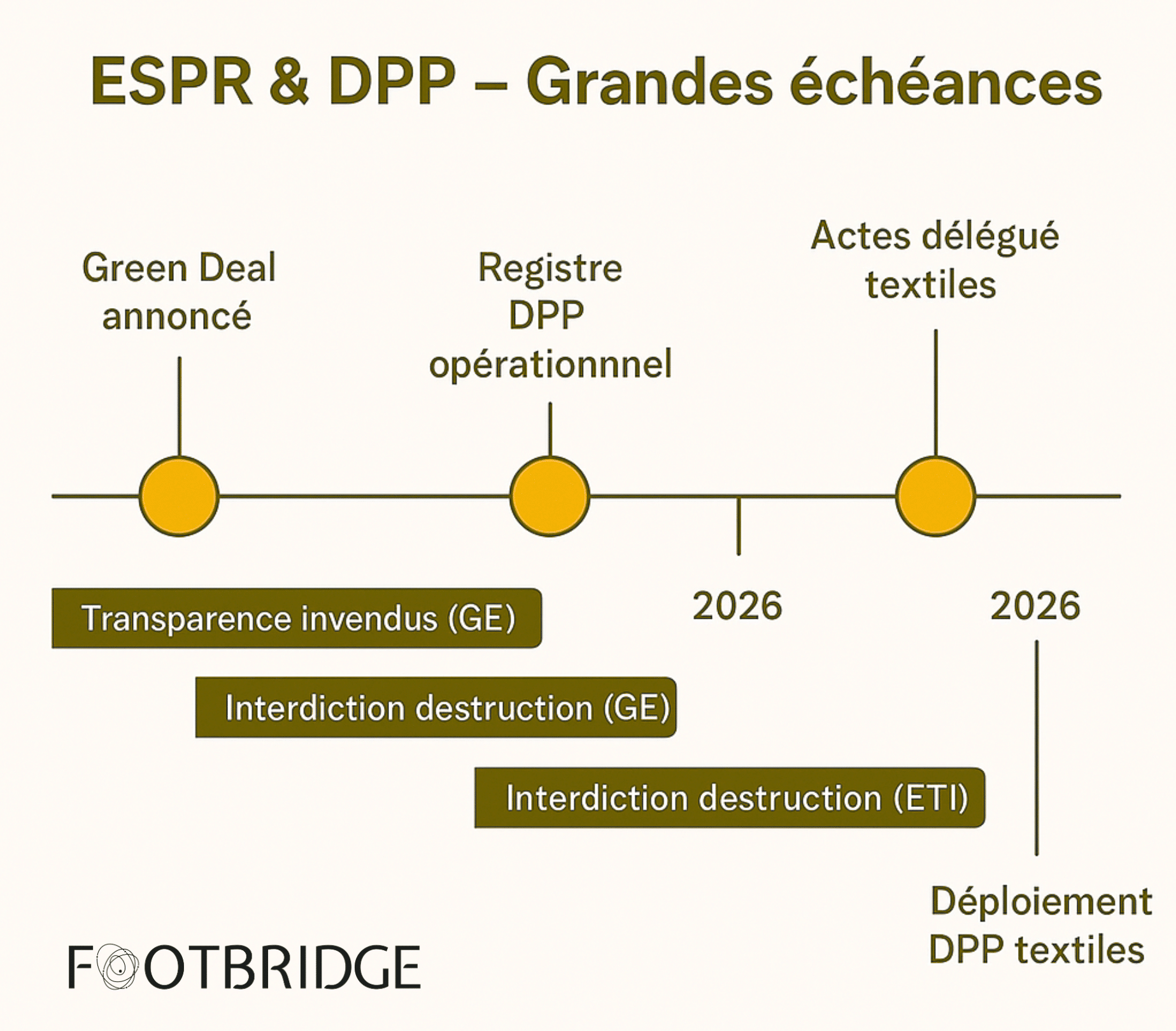

Schedule a demoTimetable and key milestones (2019-2030)

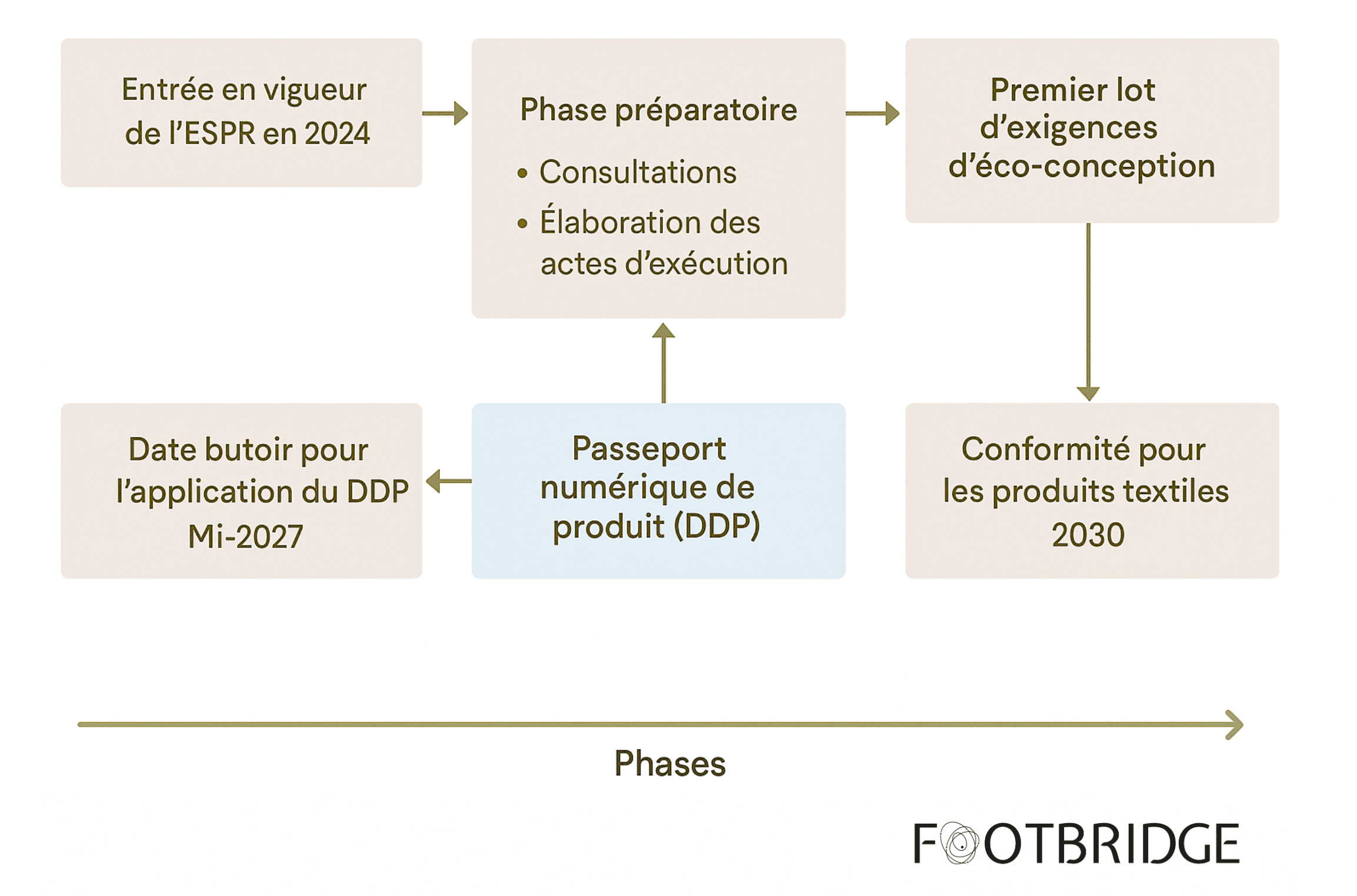

There are several key dates to bear in mind when it comes to implementing these new obligations:

- 2019: announcement of the European Green Deal.

- 28/06/2024: publication of the ESPR regulation in the EU Official Journal.

- 18/07/2024: ESPR comes into force.

- 07/19/2025: transparency on unsold goods for large companies.

- 07/19/2026: destruction ban (GE) + implementation of the DPP register.

- 2027: adoption of the textile delegated act; start of DPP obligations by product families.

- 2028-2030: gradual deployment of requirements and passports.

- 07/19/2030: ban on destruction for ETIs/medium-sized companies; first formal ESPR assessment.

By this date, all companies above small business status will be subject to the same requirements. The year 2030 is also the target date for the Commission’s first overall assessment of ESPR implementation. In other words, the coming decade will be decisive in profoundly transforming the way industry designs its products.

Who is concerned? European and non-European companies

Extraterritorial scope: all products sold in the EU must comply with the requirements, even if manufactured outside the EU. Importers and distributors are legally responsible for compliance.

The practical implications of these standards differ according to company size and resources:

- Large companies (≥250 employees): first to be targeted (reporting 2025, ban 2026). They must rapidly structure their data governance, eco-design and unsold goods strategy.

- ETI / medium-sized companies (50-249 employees): deadline until 2030 for the destruction ban, but need to anticipate (the delegated acts will also apply to their products).

- SMEs (<50 employees): weaker direct obligations on unsold products, but identical product obligations in the long term. They will have to provide data to their customers (large groups) and align with PLR formats.

ESPR can also be seen as a catalyst for innovation: small structures are often agile and creative, they can invent new ways of producing eco-responsibly, and find sustainability a powerful marketing argument. What’s more, many small ethical fashion brands already exist and have integrated sustainable materials, repair, recycling, etc. from the outset. – For them, the regulation will simply consolidate a competitive advantage they already possess.

However, care must be taken to ensure that harmonized requirements do not create excessive barriers to entry for smaller players. The European Union is aware of this, and will seek to prevent the digital passport from becoming a “bureaucratic monster” for very small businesses.

Constraints… and opportunities

Constraints to anticipate

- Data collection and reliability: materials, suppliers, processes, LCA. This requires a robust information system, data entry and quality control processes, and the commitment of suppliers.

- Initial costs: IT upgrades, product redesign to integrate eco-design, labeling, team training.

- Regulatory complexity: monitoring delegated acts, updating procedures, monitoring markets. Legal risk (sanctions, market withdrawals, consumer actions).

- Pressure on the supply chain: need to demand data from each link (sometimes located outside the EU), check accuracy and adapt supplier relations.

Opportunities to seize

- Product innovation & differentiation: designing more durable items (recycled/biosourced materials, modularity, repairability) can become a strong selling point.

- Operational efficiency: fewer unsold items, better end-of-life management, material/energy efficiency = long-term savings.

- Access to new markets & financing: “green” tenders, ESG investors, preferences in public procurement, labels.

- Strengthening customer relations: the PLR offers enhanced transparency, opens the door to services (repair, trade-in, second-hand), and combats greenwashing through factual evidence.

Action plan in 6 (real) steps

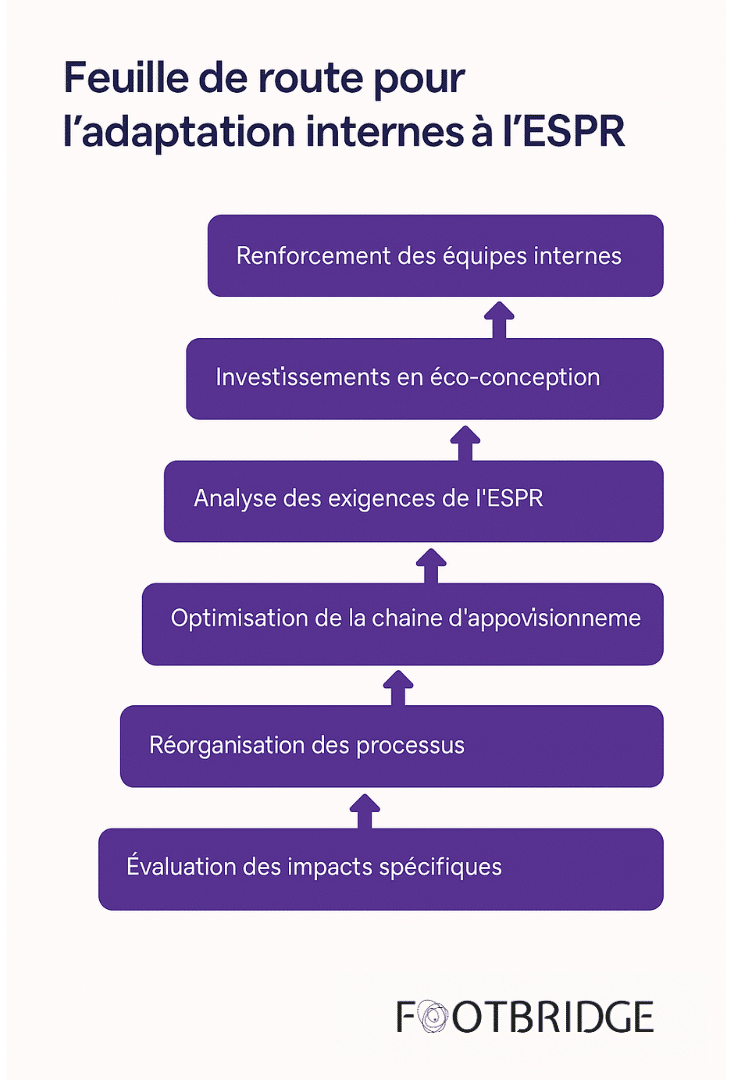

Faced with the scale of these changes, it’s crucial for fashion players to get organized now to ensure a successful transition, combining regulatory compliance with economic sustainability. Here are a few steps and courses of action to achieve this:

1. Training & auditing (starting now)

Understand ESPR/DPP requirements and map your data, products and gaps. Define your priorities (star products, volumes, risks). An internal audit of the existing situation is useful to identify gaps that need to be filled:

- what data do we have on our products?

- Where are our gaps?

- Which products would be non-compliant if the criteria (durability, materials) came into force tomorrow?

2. Data & traceability tools

Choose an interoperable, secure solution to collect, store and share information (composition, LCA, certificates) and generate the PLR. The aim is to be in a position, when the time comes, to easily generate digital passports and feed the European register, without having to chase after missing information. Early investment in these digital tools is a strategic move: they are, in a way, the “pipes” that will enable information to circulate without too much friction.

3. Integrate eco-design into the development process

Set internal criteria (durability, repairability, recyclability, recycled content) and train designers/purchasers in these new parameters. Providing style/development teams with impact-measurement tools during the collection creation phase makes it easy to make the right decisions when making this transition.

4. Involve the supply chain

It’s vital to involve the entire supply chain in the approach. This means renegotiating contractual clauses, supporting suppliers, pooling sector-specific initiatives, and consolidating sourcing with greater transparency. But this also implies clear commitments on the part of principals.

In short, adopting a collaborative approach across the value chain is a win-win situation: it ensures the consistency and reliability of sustainability information at every stage.

5. Prepare communication & customer experience

Think of the QR code as a point of contact (care instructions, recycling information, verified storytelling). Avoid greenwashing: every claim must be linked to verified data.

The watchword is educational transparency: translate technical data into understandable and attractive messages for consumers, so that they can derive value from them in the act of buying.

6. Control and continuous improvement

Set up KPIs (reparability rate, % recycled material, emissions per product), compare LCAs, adjust for each collection.

Anticipation really is the key: the earlier we act, the more we can smooth out costs over time, test on a small scale, and avoid last-minute panic. What’s more, you’ll reap the rewards more quickly (savings, new sales linked to sustainability, etc.), reinforcing economic sustainability while moving towards a more responsible model.

Footbridge: a “DPP-ready” platform for turning theory into action

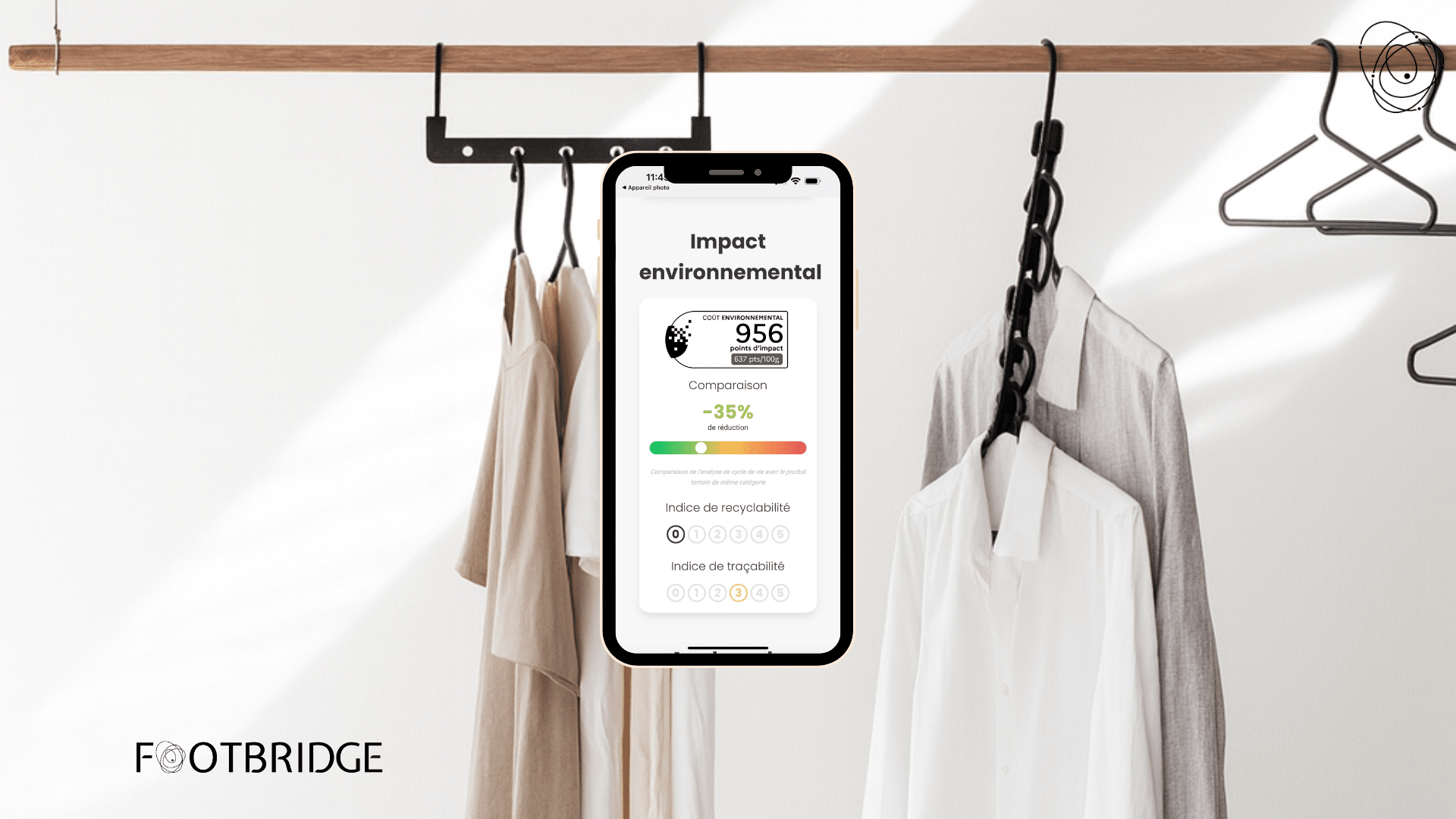

Example of a digital product passport for a garment, accessible via a QR code, thanks to the Footbridge platform.

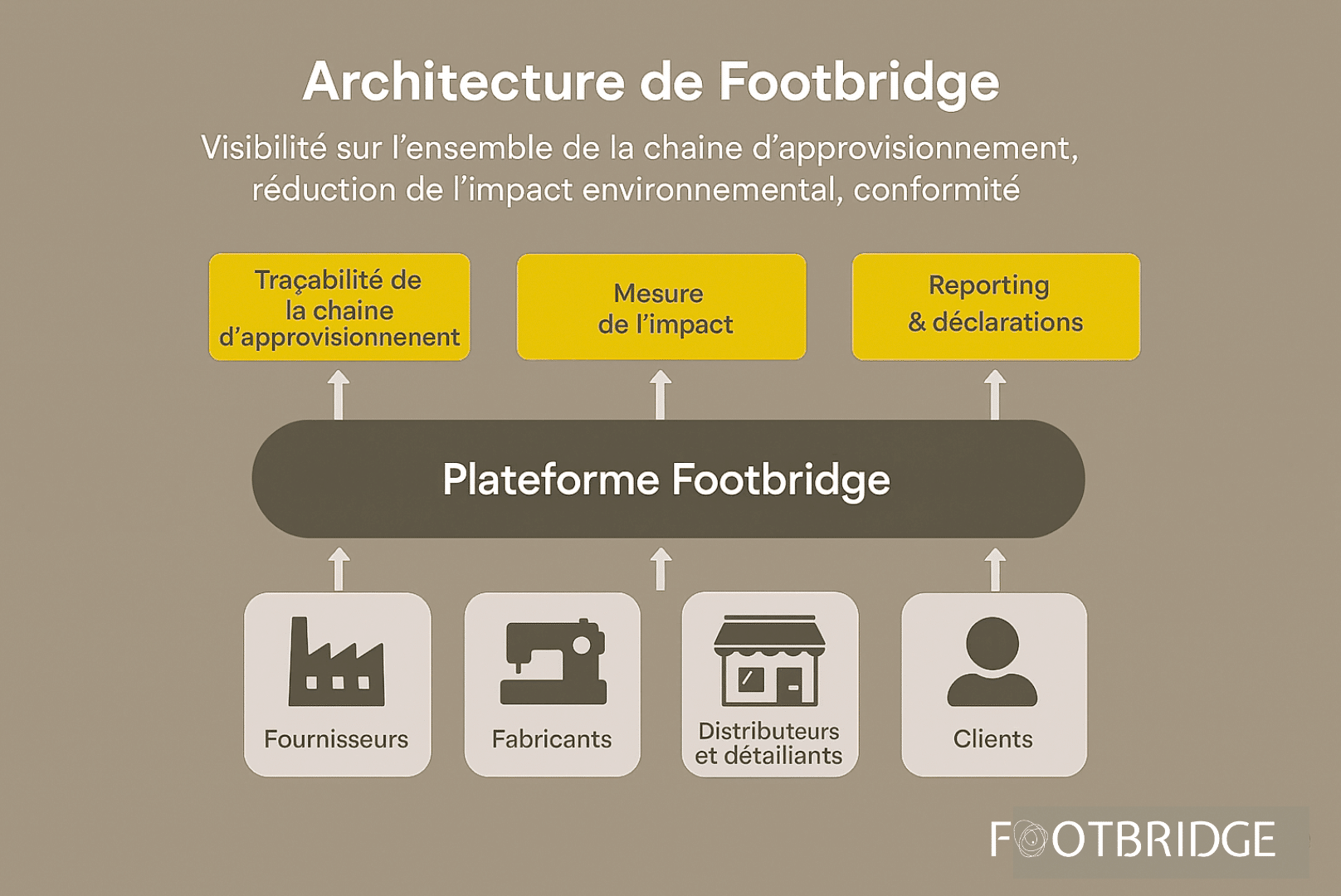

To meet these challenges, Footbridge offers a SaaS platform designed specifically for the fashion industry:

- Supply chain traceability: secure, verifiable collection of information on each purchase order from all players.

- Integrated impact analysis (LCA): calculation of environmental indicators over the entire life cycle, decision support (choice of materials/processes). Environmental score calculation.

- Automatic generation of PLRs & QR codes: by the scheduled deadlines, formats complying with European specifications and APIs to feed the PLR register will be made available.

- CSR reporting: data consolidation and analysis via Dashboards collection, dynamic dashboards.

- Consumer information: provide the transparency consumers expect and regulatory information with the Footbridge app.

By centralizing data, Footbridge simplifies compliance and creates value: better risk control, tangible proof for your customers and investors, cost optimization through data.

A shifting political context, but a steady course

It is true that the Commission has set in motion a process of “simplification” of certain regulations (Omnibus package, CSRD adjustments, etc.). This may mean additional deadlines or progressive stages. But the ESPR has been adopted and the first deadlines have been set: the circular economy is a sustainable trajectory, not a fleeting trend.

So it’s better to take advantage of the time remaining to structure your data and processes, rather than hoping for a step backwards that won’t come.

CONCLUSION

ESPR and DPP mark the start of an era of sustainable and traceable “by design” products. For the fashion industry, this represents a cultural and operational revolution: we’re no longer satisfied with “greening” communication, we’re proving it with data. Companies that make the commitment now will save time, avoid last-minute cost overruns and gain a lasting competitive advantage: a better image, stronger customer relations, operational efficiency and access to new markets.

Relying on a solution like Footbridge can turn regulatory constraints into performance drivers. It’s up to you: map, tool, eco-design, collaborate… and give your products a digital passport that tells a controlled story – your story.

The result: resilience, competitiveness and a real contribution to more sustainable fashion.

Need support? Contact Footbridge for a DPP-ready diagnosis and action plan.

Useful links :

- Text of the ESPR regulation(JOUE) : https://eur-lex.europa.eu/legal-content/FR/TXT/?uri=CELEX:32024R1781

- European Commission– Digital Product Passport : https://single-market-economy.ec.europa.eu/sustainability/sustainable-products-initiative/digital-product-passport_en

- EPRS study (European Parliament) – ESPR : https://www.europarl.europa.eu/RegData/etudes/STUD/2024/757808/EPRS_STU(2024)757808_EN.pdf

- DEFI – ESPR presentation (July 2025): https://www.defimode.org/wp-content/uploads/2025/07/DEFI_ESPR_FR.pptx.pdf

- AGEC law (France) & environmental textile labelling: https://www.legifrance.gouv.fr/jorf/id/JORFTEXT000041369391 – https://www.ecologie.gouv.fr/affichage-environnemental

- Footbridge Site : https://footbridge-impact.com