The Leather Working Group is a non-profit organization dedicated to reducing the impact of the leather industry, founded by companies such as Adidas, Clarks, Ikea, Nike, Marks & Spencer, Timberland…

The organization, which has 2,000 members in 60 countries, has developed an environmental certification framework for the entire leather suply-chain (footwear, leather goods, etc.). It is currently the only certification for this sector. It has just published a report on the life-cycle analysis of leather.

Sommaire

Summary of LWG’s LCA report on leather

The LWG commissioned Life Cycle Assessment (LCA) report aims to evaluate the environmental impact of leather production, from breeding to finished leather, according to ISO 14040:2006 and ISO 14044:2006.

The 3 objectives of the study

- Provide an up-to-date, scientific assessment of the environmental impact of bovine leather production.

- Identify critical points to guide the efforts of manufacturers, brands and stakeholders towards more sustainable leather practices.

- Support data-driven decisions to reduce the environmental footprint of the supply chain.

The methodology presented

- Study perimeter: From “farm to tannery gate” (cradle-to-gate), excluding finished product manufacture, use and end-of-life.

- Units of measurement: 1 m² of finished leather.

- Data: Combination of primary (tanning process) and secondary (breeding and slaughtering) data.

- Impacts assessed by category:

- Global warming potential (GWP).

- Eutrophication.

- Depletion of abiotic resources.

- Water use and consumption.

- Freshwater ecotoxicity.

The main results of the study

- Global warming (22.5 kg CO₂e/m²):

- 68% of emissions come from upstream processes (breeding and slaughtering).

- Manufacturing processes (32%) generate impacts, particularly in post-tanning.

- Water consumption (12 m³/m²):

- Most of the water used is treated and reused (97%).

- Impacts are concentrated in the upstream stages, notably breeding.

- Net water consumption (0.32 m³/m²):

- Low consumption in relation to water used, thanks to recycling systems.

- Freshwater ecotoxicity (283 CTUe/m²):

- Solid waste, followed by chemicals, are the main contributors.

- Eutrophication (0.16 kg PO₄e/m²):

- Impact mainly due to livestock farming (91%).

- Abiotic depletion (145 MJ/m²):

- Chemicals account for 46% of this impact.

Critical points identified

- Chemicals:

The chemicals used (19% of CO₂ emissions) are a major lever for reducing impacts, notably through better management and sustainable substitutes.

- Waste management:

Reuse of waste streams for higher value-added products.

- Choice of tanning (chrome vs. chrome-free):

Glutaraldehyde tanning (chrome-free) has higher environmental impacts, but may be advantageous in certain regulatory contexts.

- Possible improvements:

Increase energy efficiency.

Adopt renewable energies for plants located in countries dependent on fossil fuels.

Limits and recommendations

The analysis stops at the finished leather, and does not take into account product manufacture, use and end-of-life, all of which are essential for a circular approach.

Data on animal husbandry is limited, even though it represents the bulk of a leather product’s impact.

Recommendations:

- Develop traceability of raw materials down to the agricultural level.

- Collaborate with the meat and dairy sectors to reduce impacts at farm level.

- Integrate product durability and longevity into future analyses.

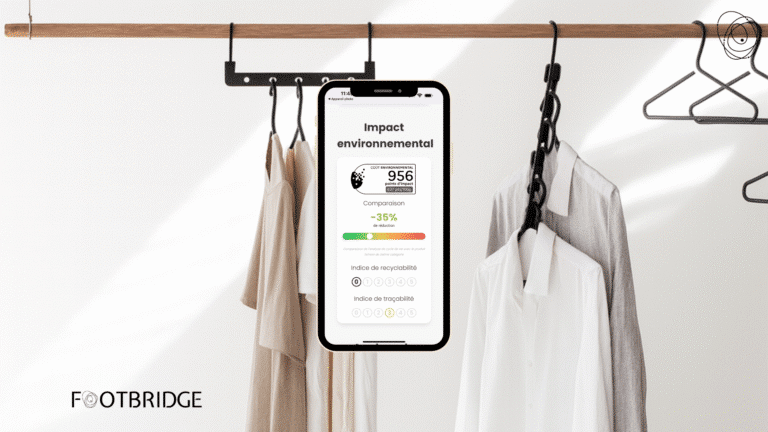

Calculate the eco-score of your clothing

Master the environmental impacts of your designs with our dedicated platform.

Schedule a demoWhy PEFCR Leather prefers mass (kg) to surface area (m²) for an LCA of a leather bag?

The choice of functional unit in a Life Cycle Assessment (LCA) is essential to ensure a fair and consistent comparison of environmental impacts. In PEFCR Leather (like PEFCR Footwear Apparel or the French Affichage Environnemental Textile), mass (kg) is used as the standard functional unit, even for products like leather bags where surface area (m²) might seem more intuitive.

This is a major methodological difference with the LWG study. Here are the main reasons for choosing mass as the functional unit:

Standardization and comparability

PEF (Product Environmental Footprint) standard:

PEF aims to harmonize LCAs between different products and sectors. The use of mass (kg) as a functional unit is more universal, as it enables direct comparison between materials of different natures (leather, textiles, plastics).

Mass is a standardized, objective measure, while surface area can vary according to the specific characteristics of the leather (thickness, quality).

Multiple applications:

By using weight as a reference, results are comparable for a wider range of products (e.g. a bag, shoes or furniture), even if their manufacture involves different material requirements.

Physical representation of the finished product

Leather heterogeneity:

Leather is a complex material with variations in thickness, density and treatment depending on its use. For products like bags, a mass-based unit better reflects the total impact of the raw materials used, as it includes additional layers (lining, reinforcements) that are not always reflected by the surface alone.

Relevant scale for impacts :

Environmental impacts, such as global warming potential or energy consumption, are more directly related to the total mass of material consumed than to its surface area.

Consistency with the supply chain

Measuring inputs:

The data available in leather industry supply chains is often expressed in kilograms (e.g. weight of hides, chemicals used).

This simplifies the calculation of environmental impacts for the various processing stages and ensures accurate traceability of material flows.

Allocation of impacts :

The environmental impacts of raw materials (notably breeding and slaughtering) are allocated to the animal according to its total weight, not its surface area. Using weight for the LCA of finished products guarantees methodological consistency.

Limits to the use of surface area (m²)

Unsuitable for certain products:

In cases where leather is used with complex shapes or significant losses (offcuts during cutting), surface area alone does not accurately reflect all impacts. On the other hand, the weight includes all losses and co-products.

Lack of standardization:

Leather surface measurement methods are not uniform across the industry (e.g., differences between full-grain leather, split leather, etc.), which could introduce uncertainties.

PEFCR’s focus on finished products

Product approach:

PEFCR is designed to assess the environmental impact of finished products as a whole, not just their main material. For a bag, the total weight includes not only leather, but also linings, fastenings and other components, making mass a more comprehensive measure.

Conclusion

The study reported by LWG provides a sound scientific basis for understanding and reducing the environmental footprint of the leather tanning stage, while highlighting opportunities for innovation and improvement in transformation processes. However, this impact assessment does not cover the entire life cycle necessary for a complete evaluation of the environmental impact of a leather product.

The choice of a functional unit in surface area (m²) is relevant for assessing specific stages such as tanning or cutting, but does not allow comparability or integration of these data for carrying out an LCA for a finished product according to the PEFCR or Ademe methodological framework.

About FOOTBRIDGE

The company has developed a leather-specific impact method in line with ISO 14040 and 14044 standards, enabling LCA and global impact measurement to be calculated for all leather products (ready-to-wear, footwear and leather goods). This service is available automatically via the Footbridge SaaS platform.

LWG report available here: https://www.leatherworkinggroup.com/fileadmin/user_upload/LWG_LCA_2024_Summary_.pdf