A complete guide for fashion brands with Good Fabric and Footbridge

Textile traceability is now a central issue for fashion brands wishing to meet consumer expectations, anticipate regulations, and control their environmental and social impact. It involves tracking and documenting every stage in the supply chain, from raw material to finished product.

But how do you set up reliable, operational textile traceability? What data needs to be collected? What technological tools should be used? Through the expertise of Good Fabric and the Footbridge SaaS solution, we explain how to successfully implement traceability in the textile sector, step by step.

Sommaire

Why has textile traceability become essential?

Quality control and industrial processes

The quality of a garment is not only measured during the manufacturing process. Compliance with best practices and certifications concerning the use of chemicals during dyeing, or the quality of the yarn, are all decisive factors in achieving a quality product.

The origin of raw materials

Knowing where raw materials are produced is crucial to ensuring that they are sourced according to quality and quantity expectations.

A major regulatory challenge

Even if European (CSRD, duty of care, ESPR) and French regulations can fluctuate. It is necessary to comply with and anticipate them. For brands, this means rigorously documenting their textile supply chain. Traceability of raw materials, suppliers and transformation processes has become a prerequisite for meeting extra-financial reporting obligations.

Consumer expectations

Consumers want textile products to be traceable, transparent about the origin of materials, production conditions and environmental impact. Integrating traceability into a product becomes a differentiating marketing argument.

A lever for controlling impact

Traceability is the keystone of any CSR strategy in fashion. It enables us to identify critical points (synthetic materials, risk zones, over-consumption of water or energy) and then take action to improve.

The traceability data collected will eventually make it possible to obtain more precise environmental scores for each product, thus highlighting eco-designed products.

What is textile traceability?

Textile traceability refers to the ability to trace all stages in the life of a textile product:

- Origin of raw materials (cotton, wool, polyester…)

- Spinning, weaving or knitting

- Dyeing, finishing, printing

- Manufacturing, assembly

- Transport and logistics

This enables us to map the supply chain, identify tier 1 to 5 suppliers, and ensure the reliability of associated social, environmental and chemical data.

Calculate the eco-score of your clothing

Master the environmental impacts of your designs with our dedicated platform.

Schedule a demoGood Fabric’s approach: structuring textile traceability

An expert in textile traceability

Good Fabric, founded by responsible fashion pioneers Nathalie and Louis-Marie Vautier, has been supporting brands in implementing their textile traceability and CSR strategy since 2016. The approach is based on:

- Detailed mapping of supply chains

- Prioritization of risks (by material, country, supplier)

- Onboarding of internal teams (CSR, purchasing, quality)

- Involving suppliers throughout the production chain

A practical methodology

Good Fabric offers a proven 5-step methodology:

- Initial traceability diagnosis

- Definition of priority materials and products

- Traceability action plan

- Data collection and verification via the Footbridge platform

- Valorization of traceability data (reporting, marketing)

Footbridge: textile traceability software for fashion brands

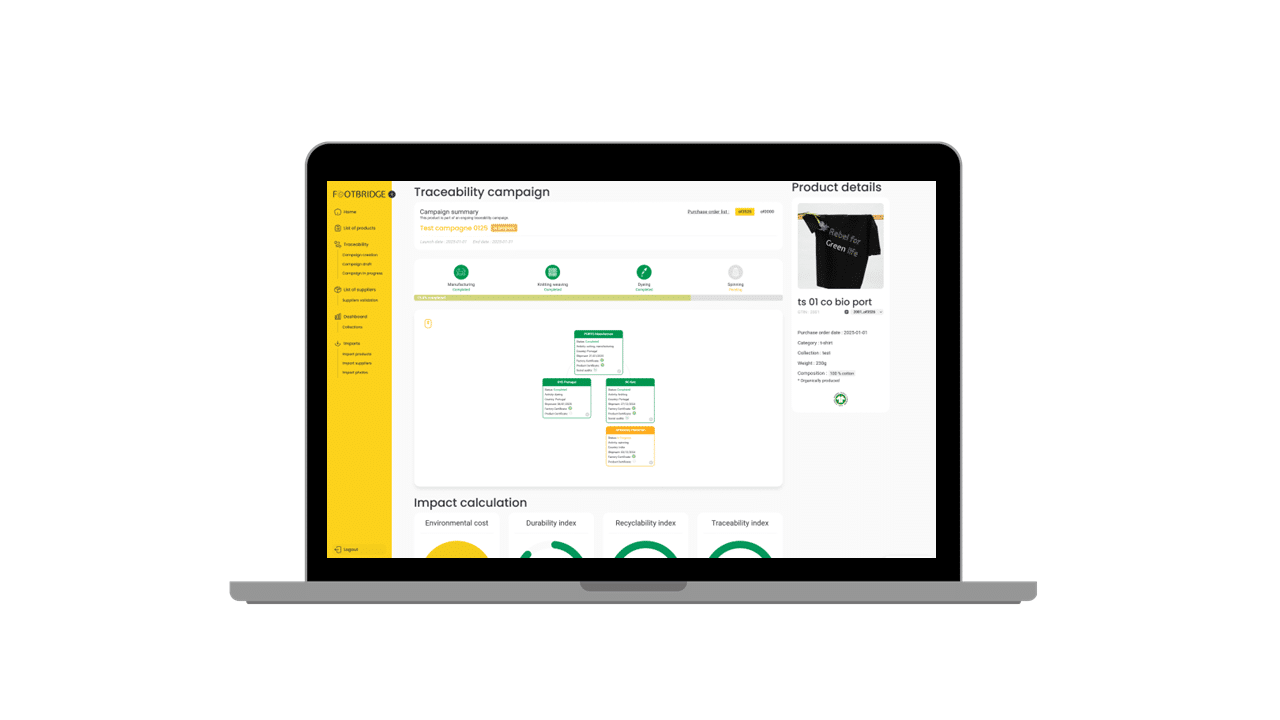

A SaaS platform dedicated to textile, footwear and leather goods traceability

Footbridge is an online textile traceability software designed to simplify the collection, validation and use of supplier data. It is aimed at brands, manufacturers and purchasing teams wishing to manage the traceability of their products centrally and securely.

Key features

- Multi-level traceability: from field to finished product

- Direct connection to suppliers

- Proof collection (certificates, documents, audits)

- Risk analysis (countries, materials, processes)

- Automated reporting for CSRD, labels, customers

- QR codes and product traceability sheets for consumers

A collaborative approach

Each player in the supply chain can be integrated into the platform to provide data and documents. Footbridge thus becomes a common repository for the brand and its partners, avoiding re-keying and increasing reliability.

How do you successfully implement a textile traceability project?

Here are the key steps recommended by Good Fabric and Footbridge to set up a complete textile product traceability system:

Step 1 – Launch the project with the right stakeholders

Bring together CSR, purchasing, quality, product and IS departments for a kick-off workshop. Objective: define issues, priorities and resources.

Step 2 – Mapping the textile value chain

Identify all direct and indirect suppliers. Go back to the yarn, the material, even the fiber. This mapping forms the basis of the traceability system.

Step 3 – Collect traceability data

Via Footbridge, suppliers are invited to submit :

- Production data

- Traceability documents (packing lists, certificates, technical data sheets)

- Social, environmental and chemical information

Step 4 – Verify and make reliable

Good Fabric analyzes data, identifies gray areas, inconsistencies or missing information, and carries out follow-up and educational activities.

Step 5 – Generate reports and indicators

With Footbridge, the brand can :

- Generate consumer mobile apps for each model, with traceability and impact data

- Prepare CSR or CSRD reports

- Create indicators by material, by supplier, by range

Step 6 – Enhance textile traceability

Well-operated traceability is a commercial and marketing asset. QR code on label, product storytelling, BtoB argument, press kit: the possibilities are numerous.

Benefits of well-operated textile traceability

✅ Regulatory compliance (duty of care, CSRD, labels)

✅ Risk reduction (human rights, toxic substances, carbon footprint)

✅ Product transparency for consumers

✅ Control of the textile supply chain

✅ Competitive edge in the responsible fashion market

Conclusion

Textile traceability is now a must for any brand wishing to combine positive impact, compliance and competitiveness. But it can’t be improvised: it requires a rigorous methodology, commitment from the supply chain, and appropriate technological tools.

This is precisely what Good Fabric and Footbridge offer: a unique synergy between human strategic support and collaborative textile traceability software. Thanks to them, brands can finally transform traceability into a lever for sustainable performance.